Since 1999, when Polyline first introduced Polyduct into the mining environment, we have continually strived to improve the product and reduce the costs. Polyline Flat Pack is the culmination of nearly 25 years of experience.

LOOKING FOR A QUOTE?

SHIPPING & STORAGE

Save freight costs and storage space on site. Hundreds of metres fit into a shipping container. Assemble during installation.

DURABILITY

Hard wearing and long life. Polyduct is highly impact resistant, corrosion free and chemically and UV stable.

ASSEMBLY

Two people, a hammer, less than ten minutes. Can be disassembled for repositioning or storage just as easily. Low (<1%) leakage when assembled.

R.O.I

When you include the cost of freight, storage, assembly, maintenance and fan power saved: PolyDuct can pay for itself within 6-12 months.

- Over 95% saving on freight & storage. 700 meters vs 20m of fully formed tube per semitrailer.

- Phenomenal Return On Investment with savings in freight, storage, assembly and power.

- Tough construction and material makes for long life and nearly

zero maintenance costs. - Available in +ve and -ve variants

SHIPPING & STORAGE

Save freight costs and storage space on site. Hundreds of metres fit into a shipping container. Assemble during installation.

DURABILITY

Hard wearing and long life. Polyduct is highly impact resistant, corrosion free and chemically and UV stable.

ASSEMBLY

Two people, a hammer, less than ten minutes. Can be disassembled for repositioning or storage just as easily. Low (<1%) leakage when assembled.

R.O.I

When you include the cost of freight, storage, assembly, maintenance and fan power saved: PolyDuct can pay for itself within 6-12 months.

- Cost

-

Handling & Installation

Handling & Installation - Characteristics

• Production: -50% Half the price standard 1200 duct

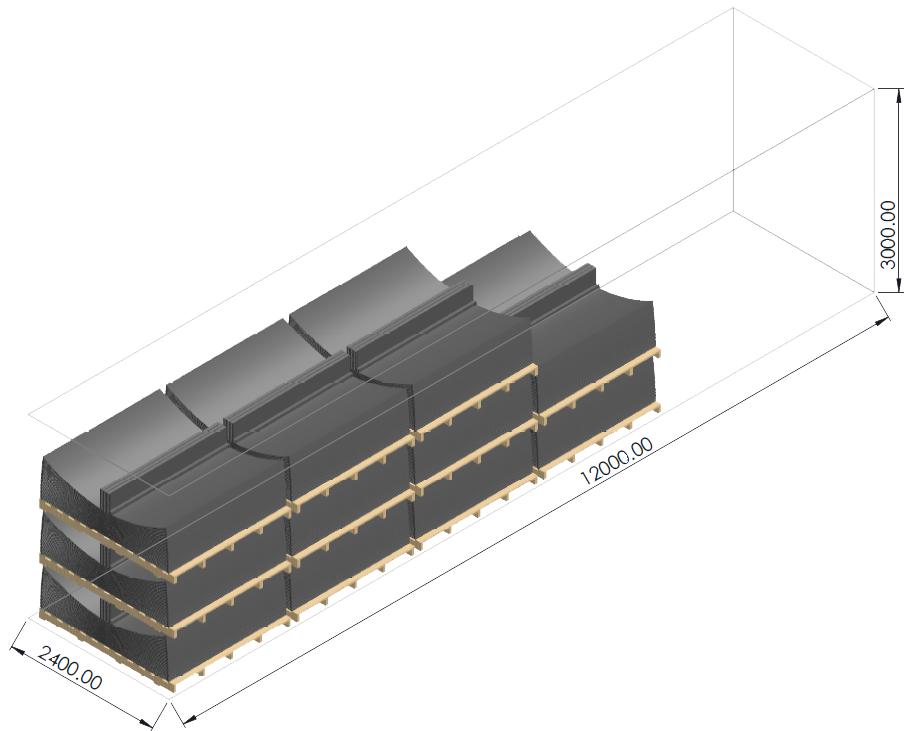

• Transport: -95% 800 Lineal Meters per 12m trailer or 735 lineal meters per 40’ Container

• Light weight (~50kg ea) -only 2 men needed

• Easily rolled and bolted above ground

• Holds in place with One Way Rope Grips

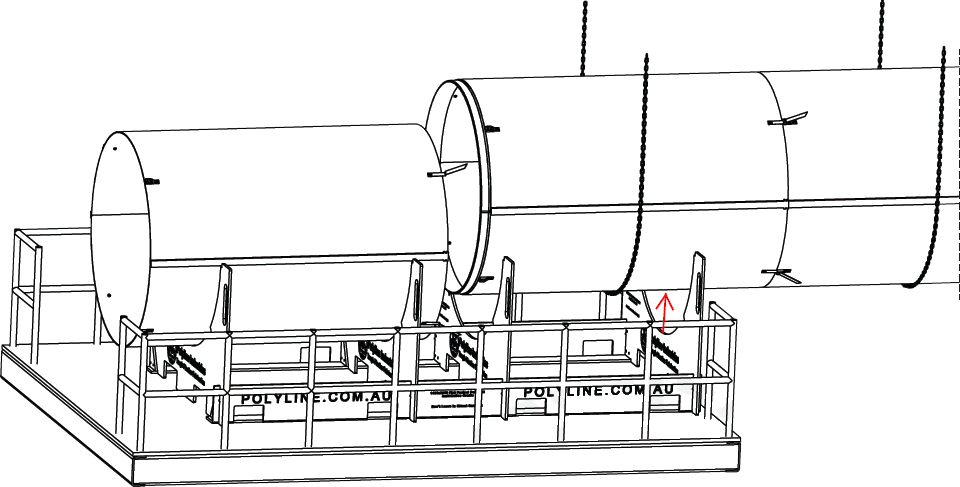

• Simply hung from the backs using chains/slings

• Inert/Won’t corrode

• Impact resistant –Low to no maintenance

• Allow for 2 degrees of deflection in any direction

• Perfect for VOD

• Reduced fan running costs compared to vent bags

- Cost

• Production: -50% Half the price standard 1200 duct

• Transport: -95% 800 Lineal Meters per 12m trailer or 735 lineal meters per 40’ Container

-

Handling & Installation

Handling & Installation

• Light weight (~50kg ea) -only 2 men needed

• Easily rolled and bolted above ground

• Holds in place with One Way Rope Grips

• Simply hung from the backs using chains/slings

- Characteristics

• Inert/Won’t corrode

• Impact resistant –Low to no maintenance

• Allow for 2 degrees of deflection in any direction

• Perfect for VOD

• Reduced fan running costs compared to vent bags

Flat Packed Poly Duct requires less truck loads to get the product to site, and less truck loads to get the ducting

underground. Save up to 95% on transport costs: rigid ducting can be limited to 10 units of Ø1400 ducting, or 20m per

truck, while flat pack ducting can fit up to 750m per truck! Instead of over 120 trucks of rigid ducting for 2km, Polylines

Flat Packed Ducting require less than 5!

Hundreds of meters can fit in a shipping container to be protected from extreme weather events, rigid duct would

require acres of storage space.

High Density Polyethylene (HDPE) is quite difficult to damage, able to withstand being hit by machines, recklessly

handled by personnel, or dropped from heights. Imagine the efficiency from a ventilated area not requiring service

crews shutting down areas for repair, or the loss of air from tears in lay flat duct.

PolyDuct is UV stable and inert, reacting to very few chemical known to man. It will have exceptional service life even in

the most corrosive of environments.

PolyDuct is highly efficient reporting an estimated <1% leakage of air at joins.

Compared to HDPE duct, Lay flat duct has very high running costs, the weight of the bag consumes energy from the fan

to inflate. Polyline has had reports that a fans running cost has been reduced by up to 50%. HDPE beats steel in

longevity and durability in an underground environment because the super-saline environment rusts steel and it can get

easily bent out of shape, Poly duct can be installed and forgotten.

If parts are lost or damaged its easy to acquire replacements, and hassle-free to install.

By using simple joining methods the entire system can be assembled by 2 people in less than 10 minutes. Polyline

supplies a graphical step by step assembly guide to ensure smooth assembly and installation.

Each section of duct takes less than 10 minutes to position and install. No heavy lifting equipment required, 2

people will be capable of moving assembled sections, and positioned onto the lifting platform. Polyline supplies an

alignment cradle, which makes fitting modules together effortless

Assembly takes about the same amount of time as installation. No dedicated assembly areas or storage areas are

required, it is possible to drive the pallets of flat packed duct to the install location and assemble them immediately

prior to installation. After the first section, an assembly team and installation team can work simultaneously to get

ventilation up and running in no time.

Flat Pack PolyDuct comes down and apart as easy as it goes together and up. The products can be uninstalled for

storage, reinstalled elsewhere, and the possibility of resale exists as well.

Flat Packed Poly Duct is 100% HDPE, meaning that once the straps and buckles are removed recycling factories may

collect the duct at no charge, or even offer scrap value. This could be a consideration for the end of life of the mine site.